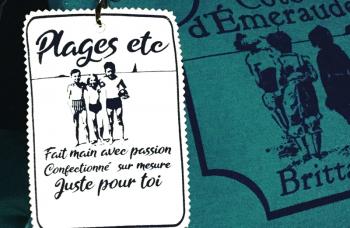

Production

The production is antique because it is based on warp and weft, that are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft (sometimes woof) is drawn through and inserted over-and-under the warp.

Then, I use the process of silk -screen printing for the design that you have selected !

I learned silk-screen printing while I was travelling in Bali. It is a print technic where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A wonderful discovery for me that I would like to share with you.

The choice for the ink is also important because I use water-based ink non-toxic high in certified pigments according to the standard Okeo-Tex standard 100 class 1.

For me, it is important to have a code of ethics where the word "environmentally friendly" was not just a word. I thought about all that quantity of fabrics thrown away and reused. It was clear that I had to do something : use recycled linen.

The steps of of recycled linen production are : classify, laundrering or linen dying, then drying in the Breton wind.

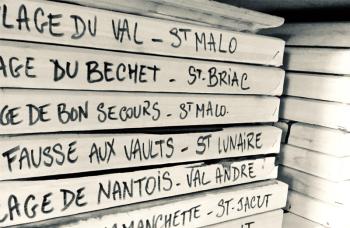

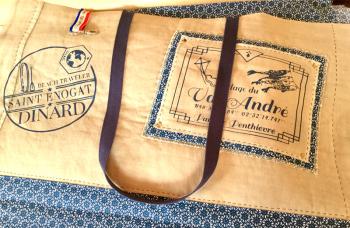

I pay particular attention to beach drawings, searching for their stories on the Breton seashore and the print work, aged and vintage look, for the authentic touch. Those beach drawings transcribe all my life in Brittany : memories on the beach, castles made of sand with my family or even bike rides.

It represents a piece of my authentic past,

that I would like to transcribe on my designs !